So, now that the “

other thread” has gone on more than 1000 posts, I figured I would start another thread in an attempt to create a conversation about EFI tuning rather than instigating a never ending flame war. As such, this post/thread is in no way, shape or form intended to start a “tuner war”, nor is it intended to serve as an attack on any individual, or group, so let’s try to keep it clean.

I come from a bit of a bit of a diverse tuning background myself, but I won’t lie, this is my first German car. In the past I’ve owned a ’91 MR2 Turbo (I still miss that car), a 2nd Gen DSM, a Mazdaspeed 6, a 350Z, an Infiniti G37 and two turbo Subaru’s (’04 WRX & ’06 STI). During ownership of those vehicles, most of them were self tuned, on various devices/methods. I’ve been privileged enough to have been able to play with several different tuning tools (on other vehicles), although since I spent to much time in the Subaru community, much of my time behind a laptop was spent with either OpenECU or Cobb software. However, I’ve also played with a few different interfaces over the years on quite a few cars, like the old UTEC, DTEC, XEDE (Shiv’s old piggyback for Subaru’s/Mitsu’s back in the day), Apexi AFC, CP-E Standback (only on Mazda’s though, actually soldered the first one in the state of CO into a buddy of mine’s old MS3), ect, have even played with other ECU tuning software outside of Subaru’s (like DSMLink) and a couple standalone’s (AEM EMS & Hydra), however, with the standalones I did little other than just try to watch and learn the interfaces haha!!

With that said, I am not a professional tuner. I have a few good friends that tune for a living, but that has never been my intention, however it has been a longtime hobby of mine. As such, I figured I would share a few of the things I have learned over the years with this community. I don’t do this for a living; I’m just an enthusiast like most of you.

I think most of us on this board understand the basic concept behind the 4-stroke gasoline piston engine. While the N54/N55 are DI, they still fall under the basic concepts of a PI 4-stroke engine, which are fairly easy to understand. On the piston’s decent from the top of the cylinder, intake valves are opened allowing the cylinder to fill with air and fuel (PI engines spray towards the valve which is open, whereas DI engines are plumbed to spray directly into the cylinder). Granted, some DI setups are able to spray fuel well into the compression stroke (haven’t researched the N54/55’s fuel timing to say where during the process fuel is injected under full load), but that’s beside the point. After the cylinder is filled with air, it makes its ascent towards the top of the cylinder in what is referred to as the compression stroke. Towards the top of the compression stroke is where the spark plug fires, igniting the compressed air/fuel, which drives the piston back down (power stroke), and of course the piston’s next ascent pushes the burnt gases out of the exhaust valves (exhaust stroke).

This is a fairly simple concept. Although the main subject focus of what I’ll refer to as “never-ending debate thread” was timing and knock/detonation, which is what I’d like to focus on.

When people are referring to degrees of timing, they are referring to the number of degrees before the piston reaches top dead center that the spark plug fires (typically up to about 40 degrees). The reason the spark plug fires prior to the piston reaching TDC is that burning the air/fuel mixture takes time, and firing the spark earlier ensures that the burn is more complete, helping to force/push the piston downward during the power stroke. While low load (and subsequently temps due to lack of pressure/friction) typically requires more timing advance in order to get a more complete burn, under higher loads the air/fuel mixture burns faster, requiring less timing advance in order to complete a full burn in time to push the piston down during the power stroke.

Advancing ignition timing too much under higher loads can result in higher cylinder temperatures, causing detonation among other things. Very simply, detonation is just small uncontrolled explosions within your cylinder that are not part of the flame front (controlled flame created by sparking the air/fuel mixture with the plug). These small explosions, created by small pockets of air/fuel within the cylinder exploding due to excess heat/pressure, can range drastically in magnitude depending on conditions. They essentially create shock waves (which is why heavy detonation creates an audible pinging sound like shaking up BB’s in a can), the likes of which can do things like crack ringlands/piston rings, put holes in pistons ect. However, obviously due to the number of unbroken N54/N55’s out there, minor detonation can be fairly inconsequential in the short term. Although over the long-term, mild to moderate detonation can exasperate particle wear, which can cause various parts to wear prematurely as particles are carried throughout the oil system prior to being trapped in the oil filter.

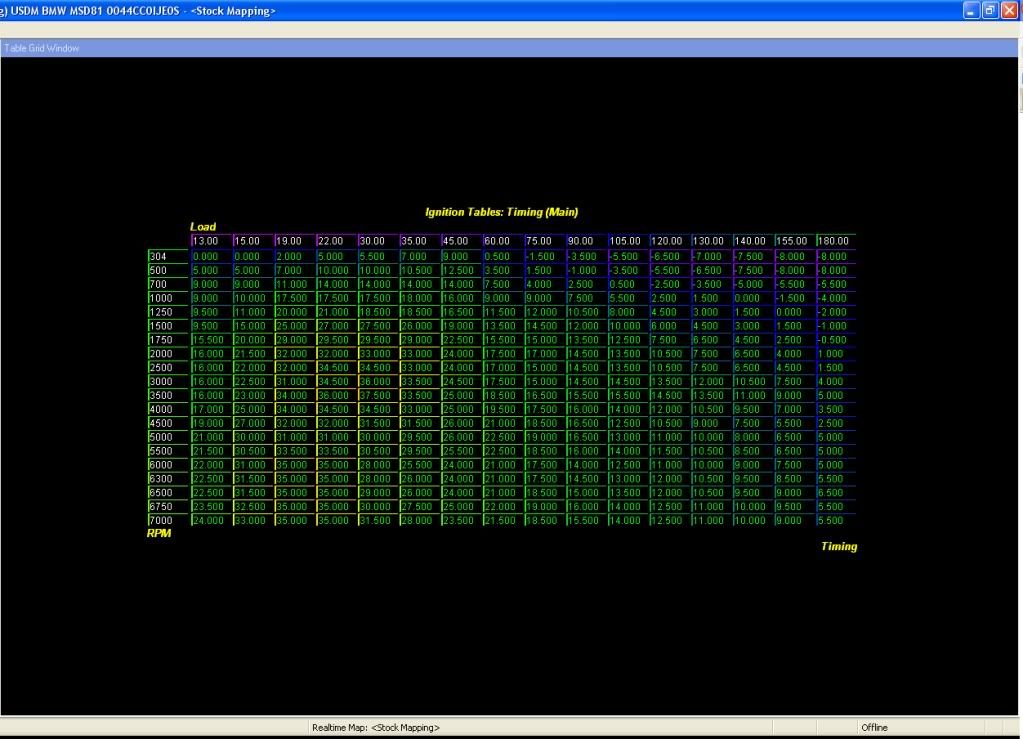

The problem that many of the knowledgeable members of this community have with certain tuning devices (such as the JB3/4), is that they do not have anyway of modifying timing, which can be far from optimum when increasing load. To anyone who has tuned a somewhat modern EFI engine, the two tables you typically spend the most time adjusting are fuel tables (for cars with Open Loop mapping) and timing. These tables are fairly easy to understand, but I’m going to focus solely on timing tables. Here’s a timing table from a WRX for example:

^^^Reading this table is fairly simple. Your axes are RPM (y-axis) and engine load (x-axis). Engine load is typically calculated from one of two sensors on most cars, either the MAF/Mass Air Flow (no MAF on N54) or MAP/Manifold Absolute Pressure (aka speed density). A MAF is basically a hotwire that requires stays heated to a specific temperature via voltage, while a MAP sensor just senses total pressure. For this discussion, the load source doesn’t matter, all the matters is that both of them essentially measure air, which is what we use for a load site.

As you can see above, as you increase load at a certain RPM, timing advance is retarded. This principle is considered universal, as the higher the load, the faster the burn. You can also see as RPM increases, typically timing is advanced slowly. This is because the piston is increasing in speed, and as such needs more advance in order to complete a full burn at the end of the compression stroke. This is why under a constant load (doesn’t happen often on a turbo car as the compressor typically doesn’t hold full boost to redline), timing should be advanced slowly as piston speed increases (RPM’s increase).

The problem many knowledgeable members have with piggybacks that don’t modify timing is that they are modifying the load signal (MAP), in order to get the DME to increase boost pressure, without the DME being able to see the actual load site. This means the DME cannot adjust timing accordingly with the increased boost pressure. If you look at enough timing tables, you can see decreasing/retarding timing advance with load is a universally accepted rule. In essence, when doubling boost on these cars, actual load is increasing by close to ~25% (give or take), with no considerations for retarding timing. Honestly, if it wasn’t for the fact that it would likely result in fuel cut, CEL’s and loss of dynamic boost control, I would almost say that a cheap MBC would offer more consistency in this regard, as at least then the DME would be able to see the actual load on the motor and adjust timing accordingly based on the factory timing tables. However, I’m pretty sure BMW (like most manufacturers) implemented some sort of throttle plate induced fuel cut for overboost situations, and would likely throw a CEL to say the least.

I will say that from what I’ve learned in the short amount of time that I’ve been a part of this community is that these ECU’s (DME’s) seem to be much more reactive than they are proactive (compared to other vehicles), which I would say is the reason why we don’t see more blown motors IMO. The fact that fueling is closed loop full time (no preset load site based table) is evidence of this. These cars also seem to have highly sensitive knock sensors and are able to react quickly to these inputs. The direct injection cooling factor and placement of the injectors (close to TDC & the plug vs in the side of the head like some other DI cars) surely helps with making them more detonation resistant. Increasing load by ~25% without allowing the ECU to see the increase in load to adjust accordingly on other port injection turbo cars is a recipe for a blown motor in a short amount of time.

However, while less than optimal, the on-the-spot adaptability of these DME’s allows for blind increases in boost without any major consequences (at least not in the short term). While I do not advocate mindless flaming or instigation, at the same time I will agree with others in that relying on the knock sensor to set your base timing maps is far from optimal. When the DME senses light knock loads (it’s a good thing these aren’t rotaries, people would be replacing apex seals right and left haha!!), it pulls often drastic amounts of timing. While the speed and efficiency of the DME is impressive, saving motors from catastrophic failure, this does result in reduced consistency to say the least. Many dyno graphs with various dips are evidence of this. While using the factory boost level timing tables would be considered very aggressive, and on a clean run (preferably with higher octane fuel & cool ambient conditions) will produce impressive power numbers (comparable to competitors), at the same time, the result will not be as consistent as competitors who are more proactive with either allowing the DME to see full load (flash based tuning) or at least offsetting timing for the increased load (ala Procede via CPS offsetting ).

Obviously there is enough evidence to show that a basic JB3/JB4, on a “low-er boost map” is not going to cause a catastrophic failure, as the knock sensors are sensitive enough & the DME reacts fast enough to stave off major detonation. However, this is far from optimal IMO. Although I’m the type of person who believes in creating my own map, for my own car, at my elevation, running fuel I normally run in order to eliminate variables, and net optimum performance, consistency and safety out of my vehicle… but that’s a topic for another thread. Either way, I for one would concur that being more proactive (vs reactive) in regards to timing (and staving off detonation) would net increased consistency and potential long-term reliability.

Again, I am not attempting to bash anyone, or any tuning device on the market, but am simply sharing a bit of my own personal experience and thoughts on the matter. I’m not a professional tuner, just an enthusiast like most of you that’s been playing with turbocharged engines for a while now. I’m not a salesman, I have no grudges on this board, nor have I ever been sponsored by any tuning company associated with this platform. Anyone who would like to have a civil discussion about the matter, please feel free to share

Just my $.02

-Brandon

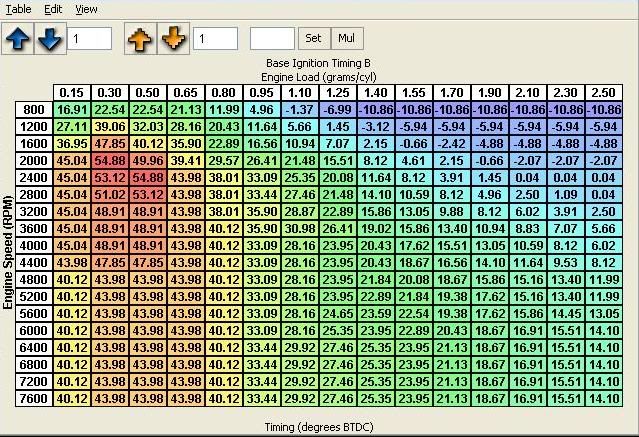

EDIT: For anyone who is interested, here is a stock timing table for the N54: