haha same. I found some good videos on youtube about it:

That has a couple parts, pretty informative but he has a fancy computer. I'm thinking what I'll do is cut out the bad section, tack in the new section and see if I can get the radiator pack and crash bar to line up along with the bumper and hood. I need the hood to get fixed first of course, or buy a new one. If so just weld it in. I don't own a welder so would have a friend do this who knows what they're doing.

Also thinking of just cutting out the bad and welding in a random piece that is around the same size. I know that if I get in an accident that won't be good but sorta just trying to do this for cheap. Cardboard is strong right? JK

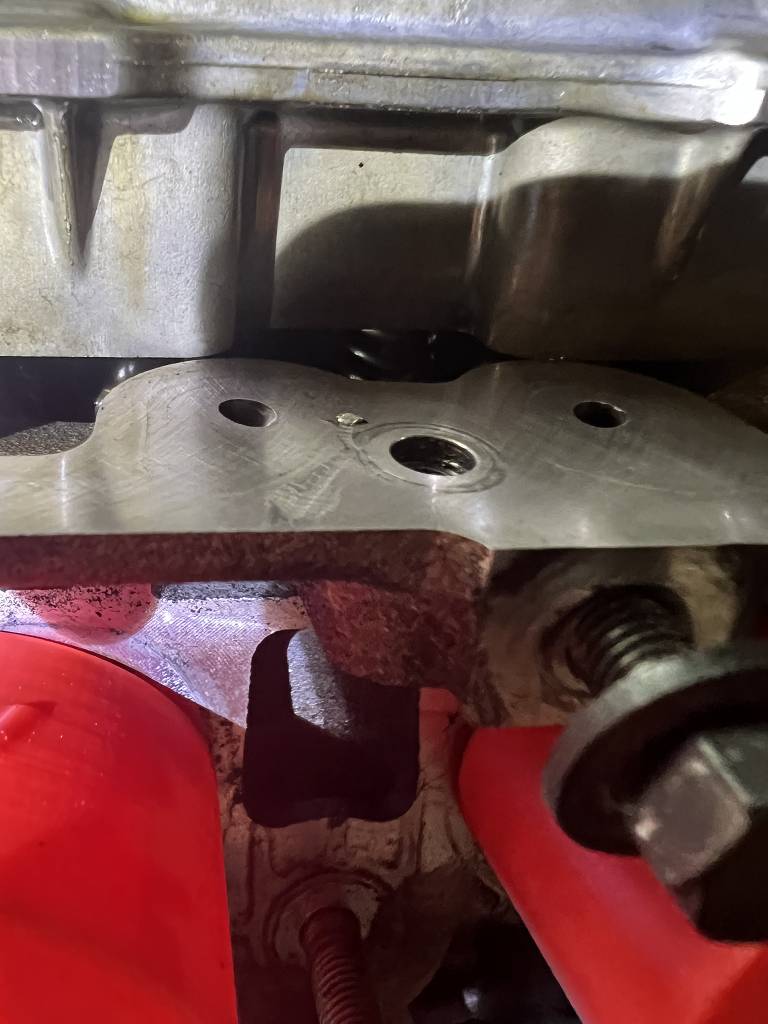

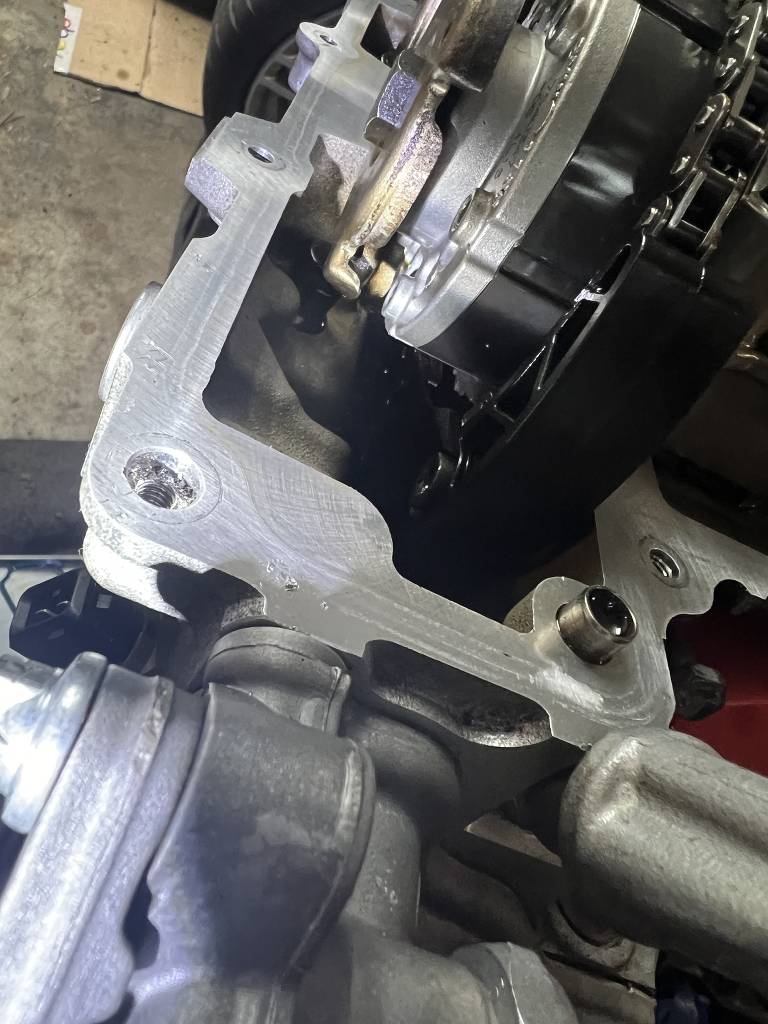

I worked on the valve cover gasket last night and was a little annoyed...someone was pretty rough with the pry bar maybe? I tried to knock down the high parts without doing more damage...I might have knocked a small chip of aluminum into the engine...how screwed am I? Anyone tear an N54 fully down? Doesn't seem too bad but I feel like I'll misplace a bolt or something lol

Looking at the top of the block will I need a shop to smooth this out or should I be okay with the new gasket? I don't wanna do all this work and just have it leak again. Let me know your thoughts.

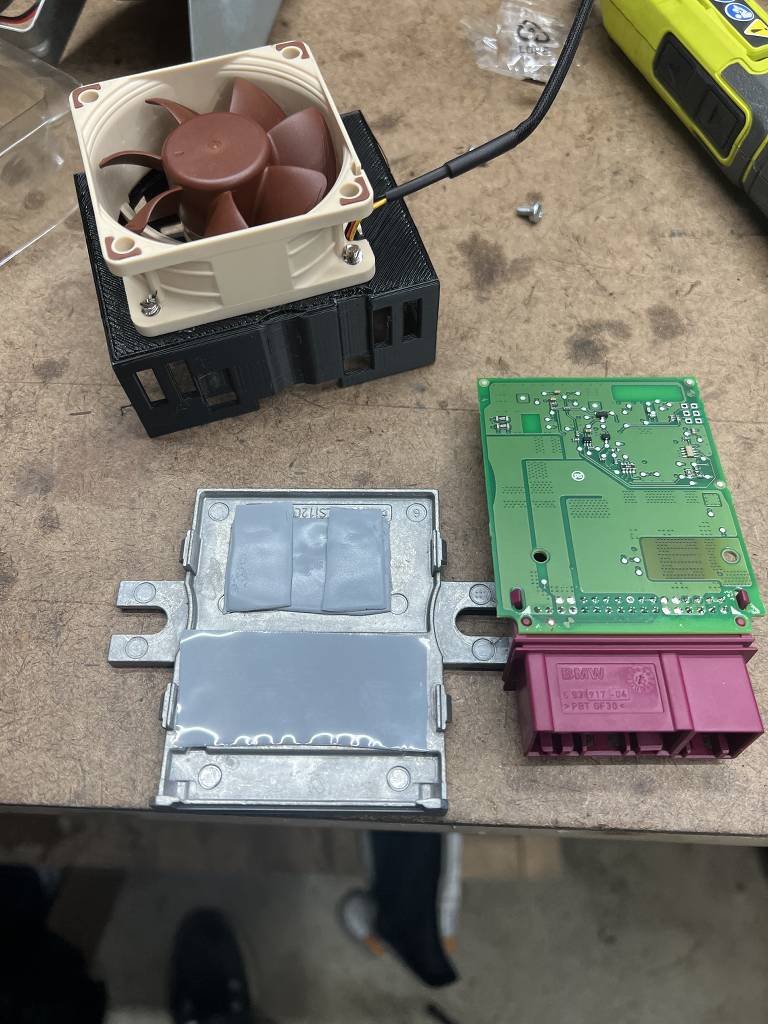

Also worked on the EKPM3 upgrades. Added the 60mm Noctua fan and thermal pads, heat sinks and a large heat sink but didn't fit so removed the big one.