Hey All, just wanted to give a quick update on the diffuser project from the past month or so. I've been working with a couple great resources and also got ahold of a stock E90 335i for baseline testing, so I now have some great data to make educated evaluations of the performance of this system

I have been working with 2 amazingly intelligent resources from the U of M; an Aerodynamicist/Professor and a Physics/Aerodynamics student. They have been very helpful with teaching me more of the intricate testing possibilities and brainstorming solutions to everything. They both have the background knowledge of aerodynamics and also a passion for cars and racing. In addition to the current setup, we're working on more testing of different side skirt placement and even running vortices on the front splitter, which would negate the need for side skirts anyways.

Here is a quick pic of how the car is sitting at the moment (without the side skirts). Since the last thread I’ve made the splitter larger and thicker, which required adding supports rods, lowered the car significantly and used even taller side skirts.

M3 Wheels 1 (1024x683)

M3 Wheels 1 (1024x683) by

MDM Enterprises, on Flickr

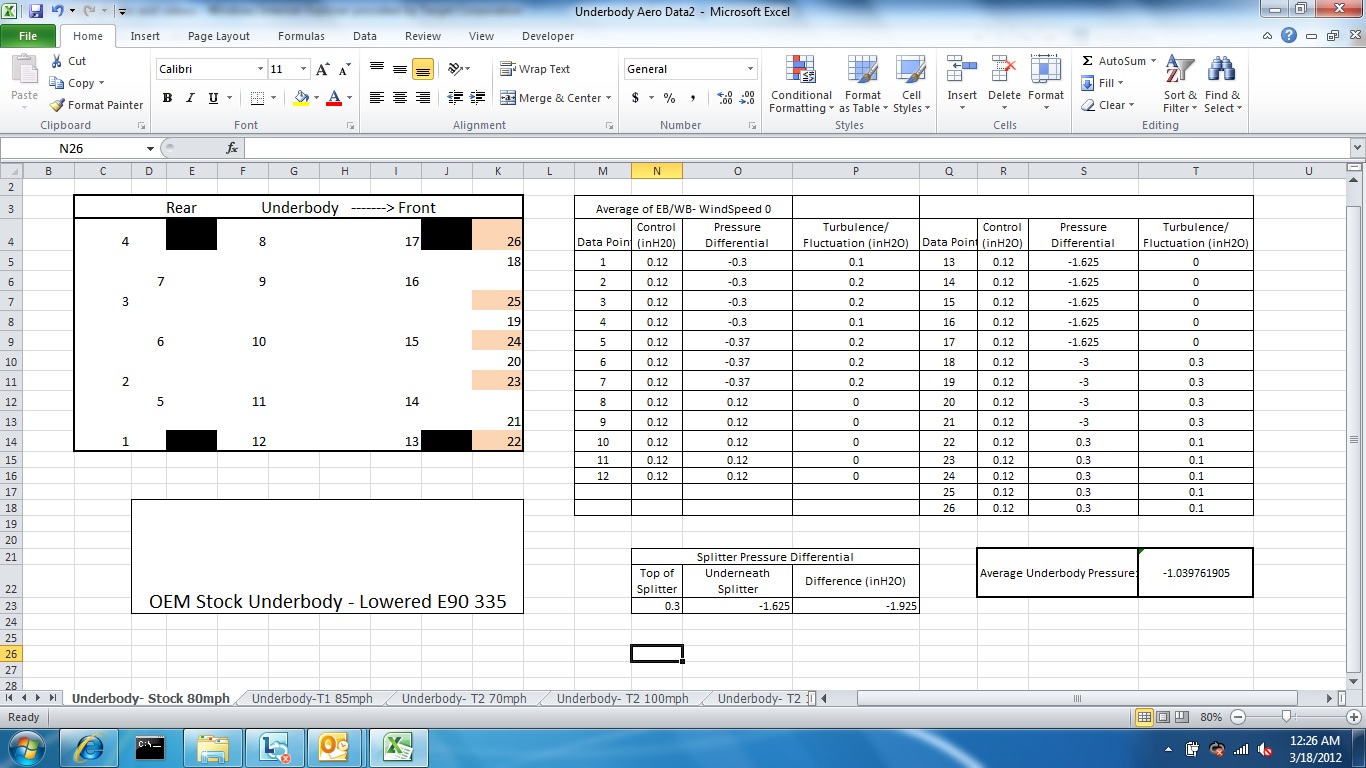

So much of this data I'm posting up might not be understandable at first glance, but try to imagine this simply as a comparison between Mark's car (stock) vs. my car (underbody system). The data I have below is showing pressure differentials at different speeds for both cars. The [lower] pressure differential is what either pulls the car to the ground, where the high pressure [underneath] pushes it up from the ground. This is a very simple, to-the-point method of testing differences in pressure. Similarly, turbulence (quick fluctuations in pressure) is very good to measure as that can both create. Sure, there are much more sophisticated, accurate and complete ways to test the system (especially the flow separation and air speeds of the rear diffuser). This testing can get extremely involved and can be more unreliable due to variances in external conditions. Regardless, the goal for my testing is to get objective data related to the overall pressure differentials of the underneath side of my ricecar, and simply testing pressures of ~40 data points with multiple magnahelics and a manometer is much more than adequate for my goals

Without further ado, here is the data from the past couple weeks:

Stock- 85mph

Stock E90- T1 85mph

Stock E90- T1 85mph by

MDM Enterprises, on Flickr

Underbody T1- 85mph

Underbody-T1 85mph

Underbody-T1 85mph by

MDM Enterprises, on Flickr

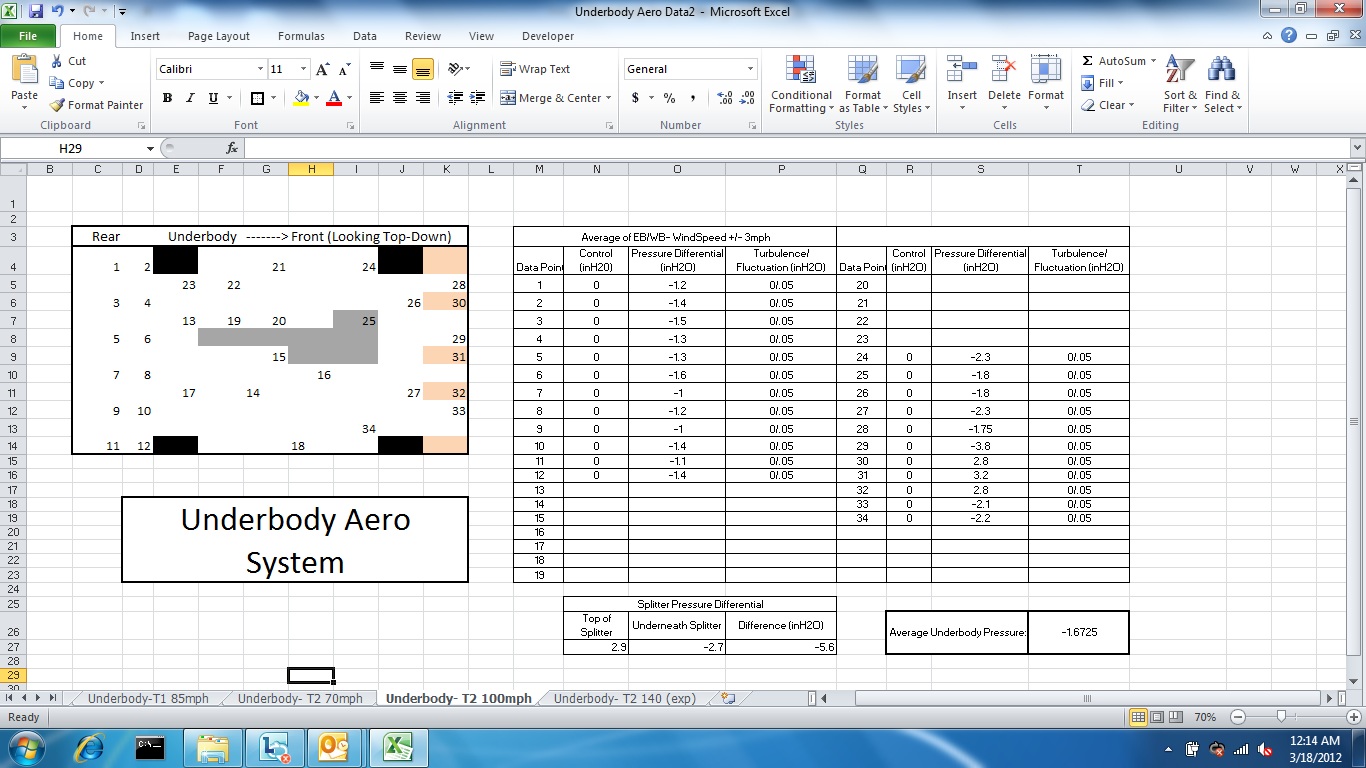

Underbody T2- 70mph

Underbody- T2 70mph

Underbody- T2 70mph by

MDM Enterprises, on Flickr

Underbody T2- 100mph

Underbody T2- 100mph

Underbody T2- 100mph by

MDM Enterprises, on Flickr

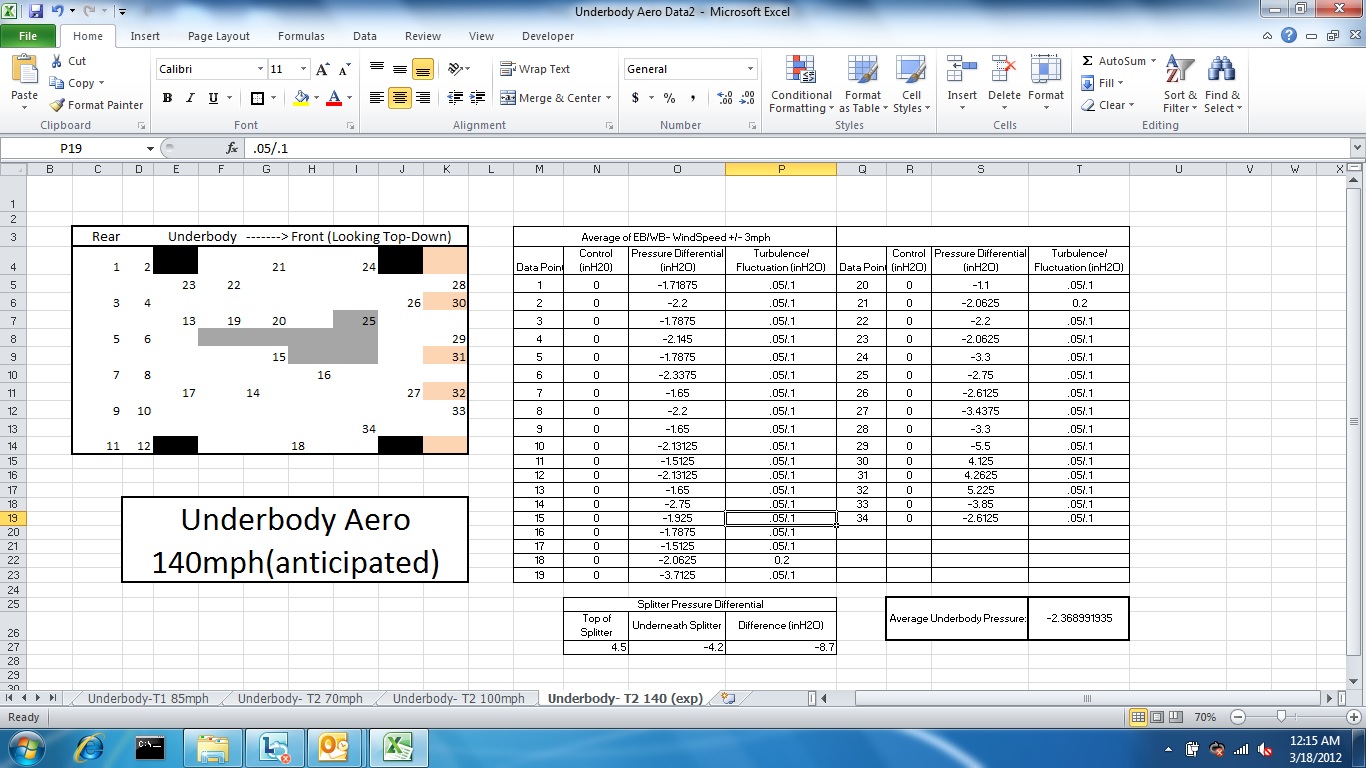

Underbody T2- 140mph- Anticipated

Underbody- T2 140mph

Underbody- T2 140mph by

MDM Enterprises, on Flickr

In summary, the downforce of this underbody system compared to stock are:

70mph- Delta of apx. 302lbs

85mph- Delta of apx. 473lbs

100mph- Delta of apx. 543lbs

140mph- Delta of apx. 746lbs

These numbers are calculated based on the average pressure in front of the front axle multiplied by the square inches of the ‘meat’ area in that same area, and similarly based on the center and rear section.

Any questions, comments, insults or jokes are welcomed. I am aware of how silly this is, and I am reminded of it multiple times a week when random teenagers ask me “Dude, that’s a sweet body kit, where’d you get it?!”

Cheers,

Brian

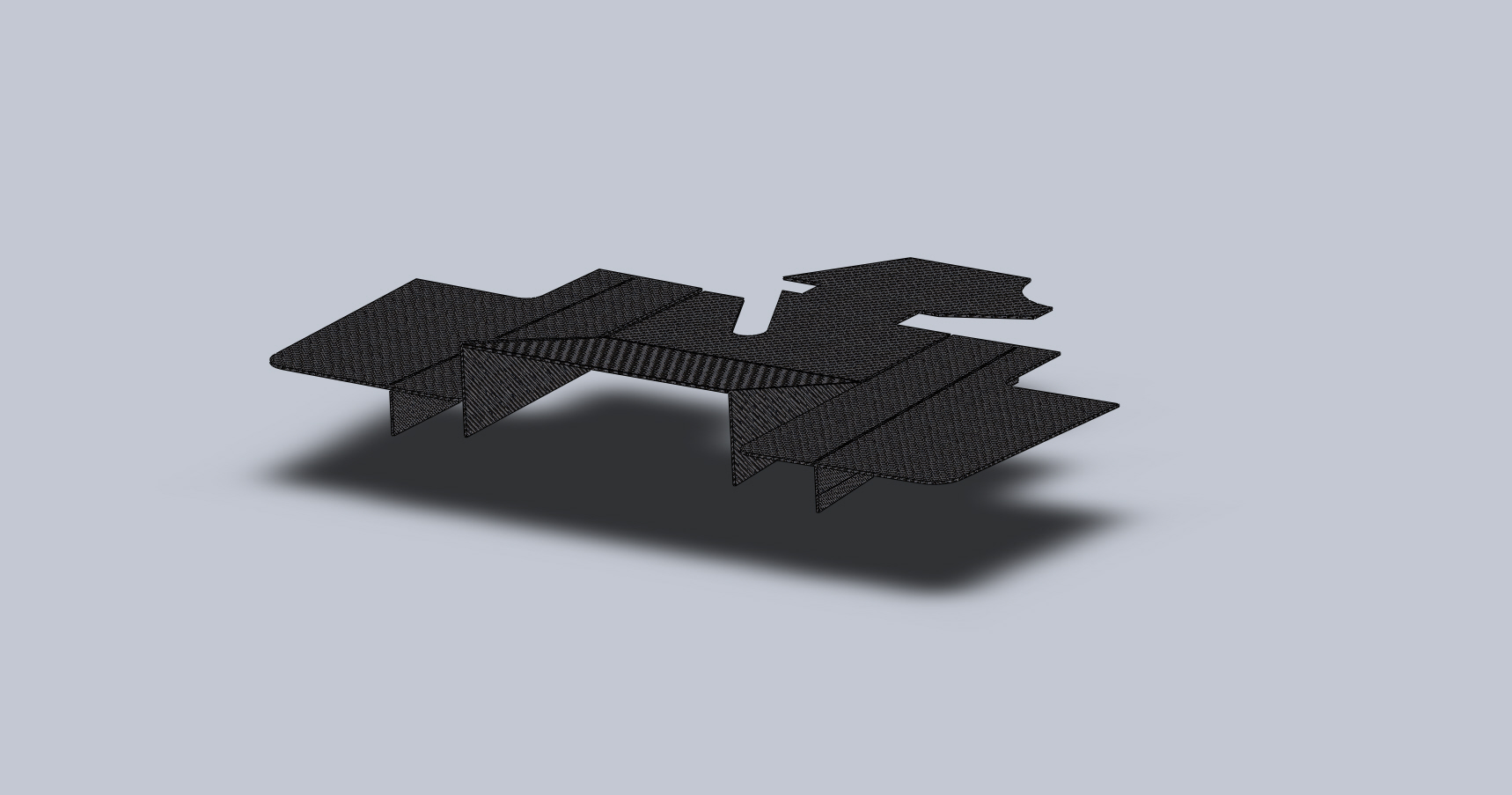

Random pics:

Diffuser CAD 1

Diffuser CAD 1 by

MDM Enterprises, on Flickr

Diffuser CAD 2

Diffuser CAD 2 by

MDM Enterprises, on Flickr

M3 Wheels4 (1024x683)

M3 Wheels4 (1024x683) by

MDM Enterprises, on Flickr