|

|

|

|

|

|

|

BMW Garage | BMW Meets | Register | Today's Posts | Search |

|

|

BMW 3-Series (E90 E92) Forum

>

E91 Trailer Project (E36 Based Trailer)

|

|

| 04-20-2015, 08:20 AM | #155 |

|

Captain

40

Rep 679

Posts |

a bit more progress this weekend...

I began shaping the foam and discovered I had make a mistake or two in my approach....I tried to contain the foam as it expanded with masking tape...this prevented the foam from curing under the tape which created large air pockets in that area...the rest of it looked pretty good, but I have to go back in with a bit more foam, then I can seal up the surface in prep for the fiberglass. I have not decided whether or not I will actually make molds of the surface which is twice as much work or simply cover the area with fiberglass, Ill still have all that foam and other material underneath and im not sure thats such a good idea...its not automotive foam, or high density stuff meant for potentially wet weather.....Ill do some more research and let you guys know what I decide.  thanks for looking! JP |

|

Appreciate

0

|

| 04-20-2015, 09:38 AM | #157 |

|

Captain

40

Rep 679

Posts |

|

|

Appreciate

0

|

| 04-20-2015, 10:23 AM | #158 |

|

these are the times that try mens soul's

37

Rep 280

Posts |

It shouldn't have to much affect on ride quality and handling. Guys over on stanceworks do this stuff quite often. With the development of air ridekits in the past 10 years it's hard to prove that they aren't as effective as your standard coilover/sport suspension.

|

|

Appreciate

0

|

| 04-20-2015, 11:44 PM | #159 |

|

Captain

40

Rep 679

Posts |

It doesnt look like much of a difference...but I was able to fill in all the gaps in the foam, cut and file it down and begin to refine the shape a bit...its beginning to make sense to me...but i realize I have a ways to go yet...

I may continue with sheetrock compound and then move on to paint. I think I am going to try to make a mold from fiberglass and then make my panel from that....Its more of a challenge than anything else, really.... so here is the progress:  thanks for looking!...any advice is appreciated..anyone ever do this kind of thing before? JP |

|

Appreciate

0

|

| 04-23-2015, 07:44 AM | #160 |

|

Captain

40

Rep 679

Posts |

updated: smooth corners!

So the smoothing continues...Its actually nice working with the sheetrock compound...the stuff builds up predictably and once past exposing the foam while sanding it dries very quickly. A simple flexible applicator (high tech pasta box material) works great on these curved surfaces.

Ive been using a guide coat of black paint to highlight the low and high spots and it works well. Im now past the cheese graters and files and am on to sanding blocks...ahhh, progress! I feel that Im getting pretty close to making the mold from layers of fiberglass mat. Ill use a release agent to help the glass come off the surface and I should be all set....  In shaping the panel, its clear that I need to carry on the body line just a bit ...the sheetrock compound works well. (I could have used bondo...but why bother?...the sheetrock compound is water soluble, has no fumes and is inexpensive...plus I dont need it to be permanent.  Of course, the other side is still really rough!.... thanks for checking in, guys! JP |

|

Appreciate

0

|

| 05-22-2015, 02:53 PM | #161 |

|

Captain

40

Rep 679

Posts |

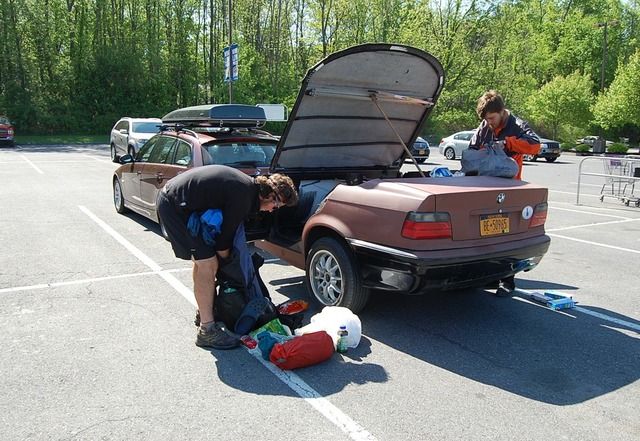

Hey, all

We hosted a couple of AT (Appalachian Trail) through hikers with a couple of hot meals and overnight accommodations and used the Bimmer and trailer to take them on and off trail.... My buddy's kid and his pal have hiked over 1500 miles so far and have another 800 left before they reach Katahdin Maine....pretty cool.....  The trailer held their fairly ripe backpacks and hiking shoes...the back seat was covered with a comforter!.....  It was a great visit and they have awesome weather, at least for a couple of days! They should be well into CT by tomorrow evening..... JP |

|

Appreciate

0

|

| 11-29-2015, 09:23 PM | #162 |

|

Captain

40

Rep 679

Posts |

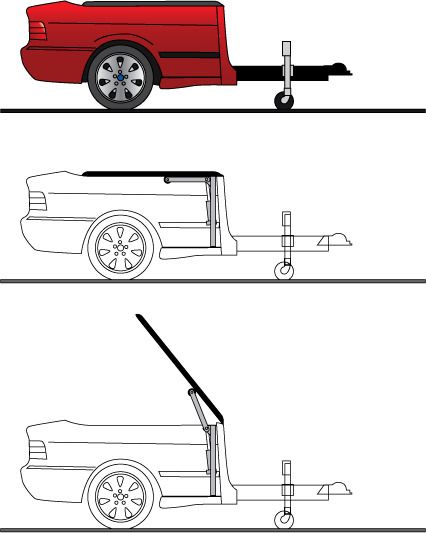

Yes, the trailer project lives on!

Hey, gang

yes, the bimmer trailer project lives on!...I am planning a tonneau cover opener and need some advise/inspiration. Ill be using a linear actuator with a 6" stroke capable of lifting 300lbs or so...(I could use an actuator with a longer stroke, but it would get in the way of the cargo area which I use all the time and those actuators are also very expensive....) I found a treadmill frame at the "recycling center" that had an incline feature and its own 120v actuator, but I wanted to stay with the 12v theme for the trailer. (inverters that can handle the 120v actuator are very expensive so I opted for the 12v actuator) anyway...I made a bit of a sketch....and here is my question....If I make the raising arms longer, does it help my cause as I only have 6" of travel with the actuator?....The mounting points are on the treadmill framework below the arms and on the back of the arms framework. Its a bit hard to describe, but basically there is a rectangular frame with hinge points that the arms attach to....  If you look at the arms, Im wondering if I make them longer, does this change the geometry at all? thanks for any advise you may have or ideas...Ill probably do a mock up too.... JP |

|

Appreciate

0

|

| 11-30-2015, 07:53 AM | #163 |

|

I'd hit it

1065

Rep 1,106

Posts |

That is quite the idea come to life. Great work getting it done. Wanna make one for my ducati to trailer my dog?

|

|

Appreciate

0

|

| 11-30-2015, 07:57 PM | #164 |

|

Major

694

Rep 1,302

Posts |

That foam/fiberglass on the corners is a bad idea. It expands and contracts at a different rate than the metal around it. Once you paint it, it's only a matter of time before it cracks.

That said, great work on this trailer. Really cool. |

|

Appreciate

0

|

| 12-04-2015, 05:23 PM | #165 |

|

Captain

40

Rep 679

Posts |

|

|

Appreciate

0

|

| 12-04-2015, 05:26 PM | #166 | |

|

Captain

40

Rep 679

Posts |

Quote:

JP |

|

|

Appreciate

0

|

| 12-04-2015, 05:28 PM | #167 |

|

Captain

40

Rep 679

Posts |

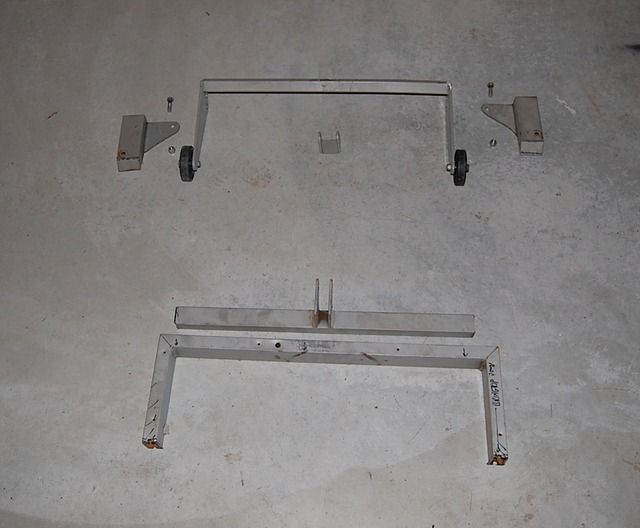

Hey all,

I have gotten closer to working out the details with my tonneau cover lift assembly. here is a shot of the pieces I am going to use from the treadmill lift system. I was able to simplify and lighten the whole thing by only using the sections from the steel frame and lift arm that I need. The whole frame weighed 20 lbs before....now Im down to about half that....  The hinges will mount to the door hinge posts on the trailer. I need to lengthen the arm assembly out from 24" to 52". Ill do that by sectioning in more steel from the frame. Ill mount the actuator bracket in the center of the arm so that it pushes up and extends the arms to a 90 degree angle...though I should not need all of that travel. I am planning on mounting the actuator just above the old transmission tunnel which is what that lower bracket and frame piece are for.... Here is the bracket that will mount to the door post:  The actuator has been shipped and should arrive next week...hopefully Ill be ready for it! thanks for looking! JP |

|

Appreciate

0

|

| 12-05-2015, 03:05 PM | #168 | |

|

Major

694

Rep 1,302

Posts |

Quote:

|

|

|

Appreciate

0

|

| 12-09-2015, 06:49 AM | #170 |

|

Captain

40

Rep 679

Posts |

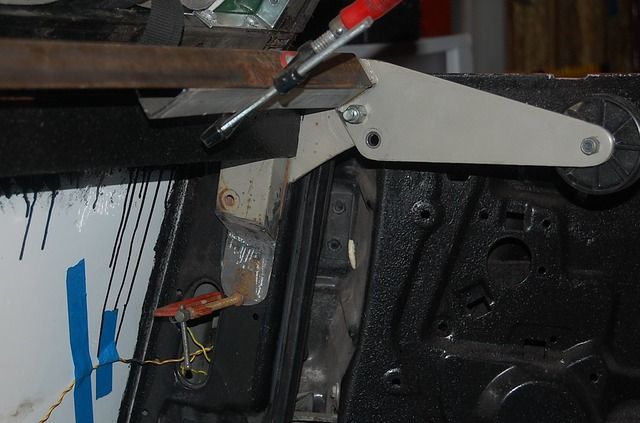

So Ive been going through one or two variations on each piece to get them to work well, fit right and look good. Ive also been trying to save some weight as much as possible.

Here is the set up with the actuator and brackets, ect...not too bad.  Right now I only have everything clamped in place but the hinge works with no binding or rubbing anywhere and it looks like Ill be able to tuck the lifting arms right up next to the inside of the doors.  I used the metal from the treadmill frame and made the bottom bracket as minimal but as sturdy as I could...its plenty strong! the welding went well too...its been a while but after a few sloppy welds, it started coming back!...  Next Ill get some material to tie the arms together with the center actuator bracket, weld that assembly together, then I should be ready for paint.... thanks as always for looking, guys! JP |

|

Appreciate

0

|

| 12-10-2015, 10:55 AM | #171 |

|

Captain

40

Rep 679

Posts |

A while back in the thread (and time) I posted about having been given an old interior hood light from a chevy truck....well I finally got around to building a mount for it and getting it mounted.

It works great...though it is very old school...we all just use our phones now as a flashlight, but what the heck...its a neat retro touch, I think!  Im Planning on getting the lower tonneau cover lift frame mounted on the trailer floor tonight then wiring everything up temporarily to be sure it all works...wish me luck! JP |

|

Appreciate

0

|

| 12-11-2015, 07:03 PM | #172 |

|

Captain

40

Rep 679

Posts |

progress continues....I was able to assemble the hinge unit this evening and hook up the actuator and remote control, ect...it works great, but there are some bugs to work out. I think I will have to lengthen the arms as the effort seems somewhat greater than anticipated at the length they are now. Im planning on posting a video, but dont know how yet...(gotta ask my kids how!)

here is the assembly just clamped to a piece of angle iron...I welded all the pieces together and it is now one unit and installed on the trailer.  in other news, my buddy gave me an old mountain bike roof rack unit and it fits great. I can now leave the front wheel in place and just clamp and bungee the bike now....  thanks for looking! JP |

|

Appreciate

0

|

| 12-14-2015, 08:20 PM | #173 |

|

Captain

40

Rep 679

Posts |

Okay, not much of an update picture wise, but I have decided to go back and do the front corners from metal...couple of good things so far....I have gotten better at shaping metal...not much better, but better (LOL)....and the foam that is there is acting as a template to really help shape the metal pieces. (like using a buck)....I am going to use 3-5 pieces per side (like I said, Im not THAT good to do them in one or two pieces) and then stitch them together....so far I have 3 of the 4-5 pieces cut and shaped and in place on the drivers side.....pics soon!

JP |

|

Appreciate

0

|

| 12-16-2015, 06:33 AM | #174 |

|

Captain

40

Rep 679

Posts |

I got some pieces cut and roughly fit in place:

I decided to refine my welding last night on some scrap metal the same thickness as my corner pieces and am very glad I did!.....it took a while to get it to the point where I wasnt blowing through the material, or just plain sloppy!....I am using a flux core wire (ran out of mig gas) and am getting good results and though its not as clean a process as with using solid wire and mig gas, it seems that it can be done.....I have to clean each weld with the wire brush and be sure I have a really good ground. The metal also has to be consistent and clean. I would like to hear back from any welders out there and see if they have had similar experiences with the flux core wire. (Millermatic, lincoln mig wire..) basically I carefully aim the weld about halfway up the last spot weld and dont really move the torch at all..but so far, as long as I am pointing it the right way, the welds are going together nicely with good penetration and no holes or gaps. thanks for looking JP |

|

Appreciate

0

|

| 12-26-2015, 11:31 PM | #176 |

|

Captain

40

Rep 679

Posts |

Happy and Merry Christmas to you all....

I got a bit more done on the trailer this week as I had some time off....Got a new controller from the manufacturer for the linear actuator and decided to take the opportunity while rewiring to tidy up the space and get a coat of paint on the inside front wall. I also began shaping and cutting the carpet too...  The actuator works great again and Im going to finish up the work on the front corners... I may take another look at the hinge unit...I think I can make it from one length of round tube that will be lighter and look less bulky. With longer lift arms that make the lifting effort less, I think I will be happier with the whole thing.... thanks for looking! JP |

|

Appreciate

0

|

|

| Bookmarks |

|

|